|

Recently launched Grade 355 Tubes – a compelling engineering solution for many applications

Grade 355 Tubes, also commonly known as Structural Hollow Sections, was launched in February in Cape Town, Durban and Johannesburg. Previously Grade 300 Tube, launched in June 1997, was available. Engineers can now use an increase minimum yield stress of 355MPa yield and an Ultimate yield tensile stress of 450MPa for designs.

Grade 355 Tube will enhance the benefits of Structural Hollow Sections and then will allow Tubes to compete on an equal footing with other steel sections. Furthermore it will assist Tubular steel in competing with other construction materials. In this article the technical benefits and new developments in Tubular Construction are discussed.

Structural benefits

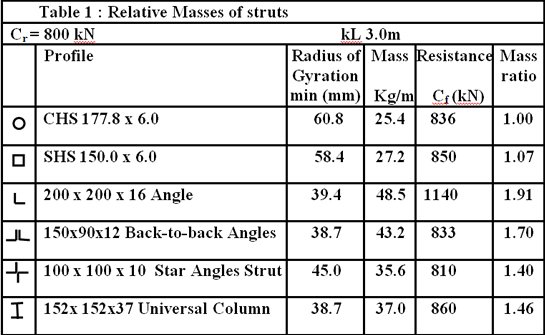

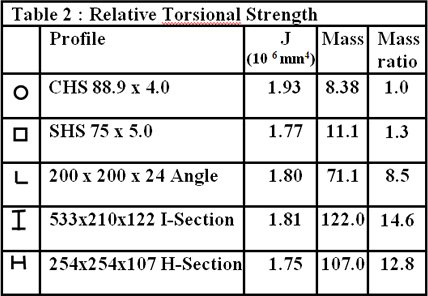

Structural benefits of Tubes are apparent when one compares various different profiles required to resist the same compressive loads. In Table 1 below various different profiles are compared in resisting a compressive load of 800kN and an effective length (kL) of 3.0m. In the comparison the Circular Hollow Section is lightest of all, followed by the Square Hollow Section. The Circular Hollow Section is 46% lighter than the 152 x 152 x 37 Universal Column. In members subject to mainly compression mass savings of up to Simply the material in a Tube is ideally positioned away from the center of gravity and hence increases the radius of gyration which then reduces the slenderness ratio thus increasing the capacity of the cross–section. Also the material distribution results in typically high Second Moment of area and consequently higher Modulus of Elasticity. Another advantage of Tubes is that the closed section increases the St Venant torsion constant hence increasing the torsional resistance of the member. This results in High flexural stiffness in all directions and a combined High torsional stiffness. A comparison between difference profile where a St Venant torsion constant of 1.7 x 10 6 mm4 is required to resist a torsion load is shown in Table 2 - Relative Torsional Strength.

Columns and beams made from Tubes do not need to be checked for torsional-flexural buckling if they fall within the limits of the slenderness ratio or when the height to breadth of these sections does not exceed 2 to 1.

Another factor often overlooked is that because of the Tubular structure is lighter and therefore more efficient smaller foundation may be required, often significantly reducing costs. This is especially applicable where poor foundation materials are encountered.

The structural efficiency also enables the Architect and Engineer with the option of reducing the number of columns in the structure. This effectively provides the Developer with more usable space thus optimizing the area under cover. Importantly it also gives the Developer and Users more flexibility in utilizing the effective floor area

Low Mass to Strength ratio

The lower mass of the structure often provides the Engineers with a competitive engineering solution. The lighter, yet stiffer structural members simplify the erection as longer spans can be pre-fabricated. Thus decreasing the cost of erection the structure on site and increasing the speed of erection.

Importantly from an environmental aspect less material is used without affecting the functionality of the structure.

Simplified Construction and Erection

The lower weight and greater lateral and torsional stiffness, trusses , girders and other members can more easily erected, and required less temporary staying. This is particularly important for long–span girders and trusses, where conventional sections construction would require lateral stabilizing members to be fitted to the top chords during lifting.

Corrosion Design

The smooth exterior presented by Hollow Section members together with the absence of gussets, re-entrant corners, inaccessible surfaces (as in double angle members) bolt heads and nuts etc. can result in a major enhancement of the ease with which corrosion resistance design may be achieved. Particular benefits can be gained on structures where access is difficult for maintenance painting such as footbridges or sign structures over motorways.

Concrete filled Tubes – an interesting option

In order to increase the load capacity of a Tubular sections the Hollow Section can be in-filled with concrete and if further strength is required with standards reinforcement. Not only is the additional strength come with little extra cost the fire resistance is increased significantly. Among other interesting application are steel framed high rise buildings.

Guidance with regard of Designing of concrete filled Hollow Sections is comprehensively covered in SANS 10162 Part 1.

Aesthetical attractive appearance

The aesthetical pleasing solution provided from Tubular Construction is derived not only from the simple outline of the members themselves, but also from the absence of such items as gussets, battens, lacing, sub-bracing, lateral ties, bolts etc. Curving of members is easily facilitated with Circular Hollow Sections, and to a lesser degree with Square and Rectangular Hollow Sections.

Other benefits

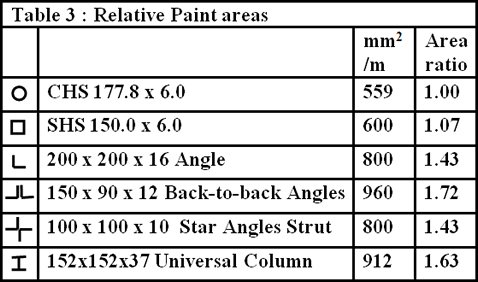

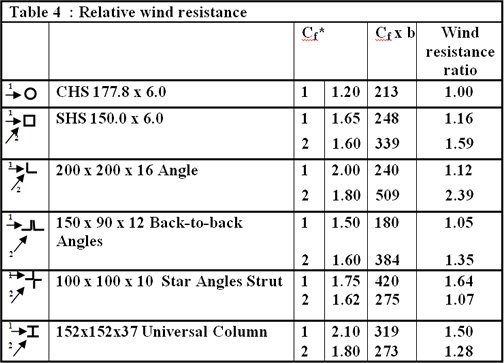

Other benefits include reduced paint areas, refer to Table 3, and reduced wind resistance, refer to Table 4.

In Table 3 the paint areas are compared for the previous design example where 800kN load and a slenderness ratio of 3.0 is applied to a member. The Circular Hollow Section has 43% less surface area than the equivalent Star Angle Strut configuration resisting the same load. The relative ease with which the painting maintenance can be done is apparent studies the various member configuration.

Similarly Table 4 compares the wind force for the same design example. A Star Angles Strut attracts 64% more force than the equivalent Circular Hollow Section.

* Based on Tables 15 and 22 of the SABS 0160-1989.

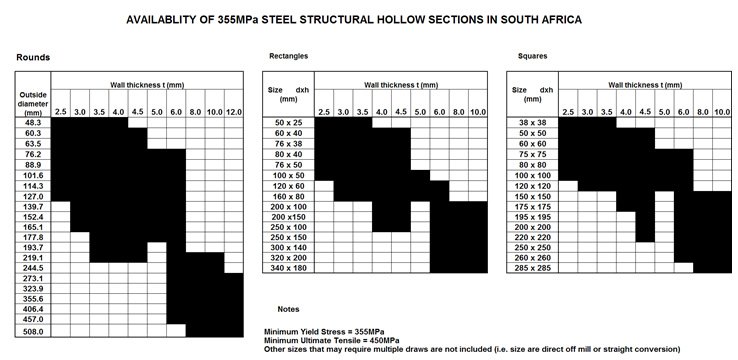

Grade 355 Tube size range

In the Table below the size range is shown. Stocking of the sizes varies from manufacturer to manufacturer.

Click Here or Image To View Large Image

Download the S355 Tubular section properties. Download the S355 Tubular section properties.

Technological Developments in Processing of Steel

The advent modern High definition Plasma and Laser profiling machines has simplified the assembly of the connecting profiles radically. This, ever developing, technology makes the profiling of tube simple. The machinery provides the fabricator with a clean ready to assemble component that can be simply welded together with ease. The machines not only profile or make slots at the ends of the members but can cut any shapes that may be required along the length of the member.

Plasma and Laser machines are supplied with either a Two Dimensional head or a Three Dimension head. Three Dimension Head is typically required for thicker material where weld preparation is required at the end of the Tube.

Conclusion - Economies of Tubular structures

It is clear that the abovementioned benefits make a strong case for using Hollow Sections in Steel structures. The argument against their more general utilization is of course based on prime input costs. The purchase price per ton of Hollow Sections is significantly higher than that of hot rolled conventional long sections, furthermore the labor cost per ton for fabrication in higher because of the greater proportion of the shop preparation and welding. However, in the final analysis, when all aspects have been carefully considered and properly assessed, in a great many applications Tubular Construction is very competitive.

In the case of members subject to mainly to compression forces, that is columns and bracing, Tubular Construction is the way forward.

By Franco P. Mordini – Business Development Specialist at Macsteel Tube & Pipe and Chairman of the Technical Committee of the Association of Steel Tube and Pipe Manufacturers of South Africa.

|